HUDA Aging Test Chamber Series

Product Types Tested in Aging Chambers

Plastic and rubber products: Tires, seals, conveyor belts, pipes and other materials are easily affected by factors such as light, temperature, and humidity during long-term use, and may experience aging, discoloration, cracking and other problems;

Electronic and electrical: Solar panels, LED lamps, electronic components and other electronic products often need to withstand high temperature, high humidity, ultraviolet rays and other environmental tests;

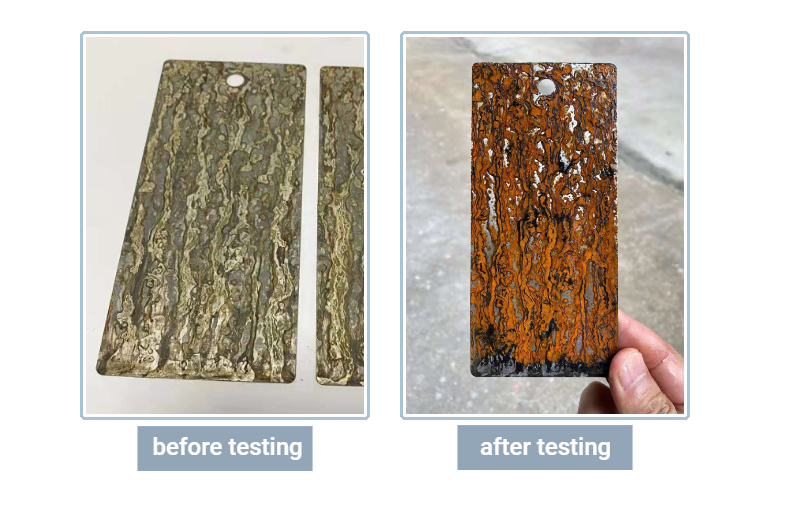

Metal and alloy materials: Copper, aluminum, iron, steel alloy, aluminum alloy, copper alloy and other metal materials are prone to corrosion in humid, salt spray and other environments;

Paints and coatings: Paints, varnishes, anti-corrosion coatings and other coatings play an important role in protecting substrates from environmental erosion.

Aging Chambers Applications:

1、HUD-E801 ozone aging test chamber: mainly used to simulate high-concentration ozone environment and evaluate the aging performance of materials under the action of ozone.

Suitable industries: rubber, plastic, wire and cable industries, and fields with high requirements for material weather resistance.

2、HUD-E802 uv aging test chamber: simulates ultraviolet radiation in sunlight to test the light aging resistance of materials.

Suitable industries: products or materials used outdoors such as coatings, plastics, automobiles, and building materials.

3、HUD-E711 xenon lamp aging test chamber: can simulate multiple environmental factors at the same time, such as sunlight, rain, temperature, humidity, etc., to conduct comprehensive light and thermal radiation aging tests on materials.

Suitable industries: automobile, construction, coatings, plastics and other industries, which need to evaluate the durability of materials in actual use environments.

4、HUD-E704 yellowing resistance aging test chamber: different exposure time and temperature conditions can be set to simulate different use environments.

Suitable industries: plastics, rubber, coatings, inks, electronics, automobiles, etc., used to evaluate the yellowing resistance of materials under light conditions.

5、HUD-E808 salt spray test chamber: mainly used to simulate the marine and salt spray environment to test the corrosion resistance of materials.

Suitable industries: automobiles, ships, electronics, aerospace, etc., fields that require the corrosion resistance of products.